![]()

Product Support

Product selection guide

![]()

( Description )

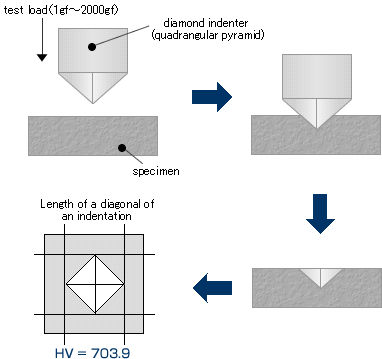

The Vickers hardness test uses a diamond indenter with the shape of square-based pyramid with an angle of 136° between opposite faces. The Vickers hardness is expressed as the quotient obtained by dividing the test load of the indenter by the surface area determined by the diagonal length of the permanent depth.

Vickers hardness testers provide consistent results to homogeneous materials regardless of the magnitude of the test load.

Also, this tester can continuously measure hardness of materials, from the softest to the hardest, using the same measurement.

Vickers Hardness Testers and Micro Vickers Hardness Testers are set to use both Vickers and Knoop indenters. (See Micro Vickers Hardness Tester)

( Applications )

・Precision parts of airplanes, vehicles, etc.

・Thin sheets and small parts that can not be measured by the Rockwell hardness tester.

・Surface hardness and cross-section hardness distribution of surface hardened materials (High-frequency, carburizing)

・Normal steel: Hard plates, this sheets, steel pipe, wire, etc.

・Special steel: Steel bar, deformed steel, wire, etc.

・Stainless steel: thin sheets, pipe

・Structural objects (tanks, bridges, etc.)

・Cross-section hardness distribution of welded joints: Hard plates used for shipbuilding, welding pipe (UO, spiral, etc.)

![]()

( Description )

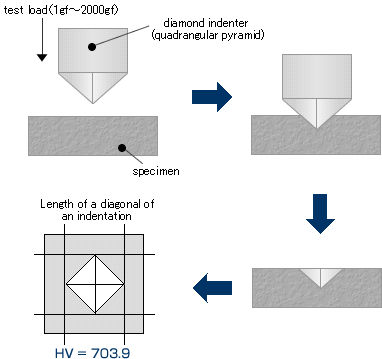

The micro Vickers test uses lower test loads and is suitable for micro-scale measuring. The Vickers method with a test load of 1 kgf or lower is called micro Vickers hardness test in Japan.

Micro Vickers hardness testers are suited for measuring a wide range of materials because its test loads are far lower than those of other hardness, and are indispensable in fields that require accurate hardness.

Micro Vickers hardness testers were developed for the purpose of measuring accurate hardness in a very wide range of fields.

Knoop hardness: Expressed as the quotient obtained by dividing the test load of the indenter, elongated pyramid-shaped diamond with its face having angles of 172°30' on the long axis and 130° on the short axis, by the projected area determined by the longer diagonal length of the permanent depth.

The shape of the Knoop indentation, unlike that of the Vickers', is a rhombus with different diagonal lengths. The Knoop method is suited for measuring fragile materials because the direction of the longer diagonal line causes little plastic deformation, and also its elongated indentation is well suited for sequentially indenting with little space between indentations. Moreover, the very shallow penetration of this method is extremely helpful when measuring very thin test materials and hardness distribution of cross-section of a very shallow surface hardened layer.

( Applications )

・Very small parts: watches, calculators, electronic components

・Plated layers, layers of special coating

・Hardness of internal metal structure

・Hardened surface of carburized, nitrided, or soft-nitrided layers: Surface hardness and hardness distribution of cross-sections

・Edges of knives, gear teeth, etc.

・Cross-section hardness distribution of weld joints: Micro-scale testing

・Surface and cross-section hardness of gold leaf, thin steel sheets, alloy sheets, fine wire, etc.

・Ceramics, glass, gem stone, tablets, bones, nonmetal materials, such as dental materials

・Surface hardness of heat treated materials

![]()

( Description )

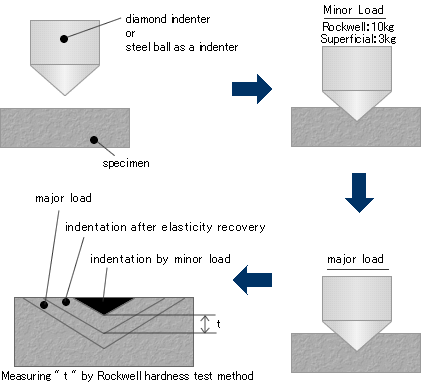

A Rockwell hardness tester employs either a diamond cone or a steel ball as a indenter. It applies a minor load followed by a major load, and then reduces the load to the initial minor. The hardness of a material is determined from the depth of the first and second penetrations of the minor load by using a linear gauge or other tools. This test is used to measure various samples regardless of the size, from extremely soft materials, such as plastic, to superalloy, at multiple stages of production, from testing raw materials to examining end products.

The Rockwell hardness test uses original scales to express the hardness of things. This method is unique having several alternative scales available by combining different indenters and test loads.

The Rockwell scale is universal, and the hardness test condition is easily identified.

Apart from regular Rockwell hardness testers, Rockwell Superficial Hardness Testers with lighter test loads, and Twin Rockwell Hardness Testers with features of both Rockwell and Rockwell Superficial hardness testers are available.

( Applications )

| - | Scale | Indenter | Minor Load (kgf) |

Major Load (kgf) |

Typical Applications |

| Rockwell | C | Diamond cone with vertex angle 120°and vertex radius of curvature 0.2 mm | 10 | 150 | Hard materials with hardness between B100 and C70 |

| D | 100 | Materials requiring loads slightly lighter than the C scale loads. (Shallow to medium case hardened steel) | |||

| A | 60 | Superalloys, thin steel and shallow case hardened steel | |||

| G | 1/16" diameter steel ball | 10 | 150 | Materials harder than tested on the B scale | |

| B | 100 | Steels with hardness between B0 and B100 when annealed. | |||

| F | 60 | Bearing metals, annealed brass, copper, and thin sheet metals | |||

| K | 1/8" diameter steel ball | 10 | 150 | Very soft materials (bearing metals and extremely thin materials) | |

| E | 100 | ||||

| H | 60 | ||||

| P | 1/4" diameter steel ball | 10 | 150 | Very soft materials (plastic, lead, and extremely thin materials) | |

| M | 100 | ||||

| L | 60 | ||||

| V | 1/2" diameter steel ball | 10 | 150 | Very soft materials (plastic, lead, and extremely thin materials) | |

| S | 100 | ||||

| R | 60 | ||||

| Superficial Rockwell | 45N | Diamond cone with vertex angle 120°and vertex radius of curvature 0.2 mm | 3 | 45 | Nitride steel, blister steel, and hard sheet materials |

| 30N | 30 | ||||

| 15N | 15 | ||||

| 45T | 1/16" diameter steel ball | 3 | 45 | Steel, brass, and bronze sheets | |

| 30T | 30 | ||||

| 15T | 15 | ||||

| 45W | 1/8" diameter steel ball | 3 | 45 | Extremely soft materials | |

| 30W | 30 | ||||

| 15W | 15 | ||||

| 45X | 1/4" diameter steel ball | 3 | 45 | Extremely soft materials | |

| 30X | 30 | ||||

| 15X | 15 | ||||

| 45Y | 1/2" diameter steel ball | 3 | 45 | Extremely soft materials | |

| 30Y | 30 | ||||

| 15Y | 15 |